You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What is the hot press curing process of moisture-proof green Particleboard

source:www.cypanlong.cn Time:2025-04-14

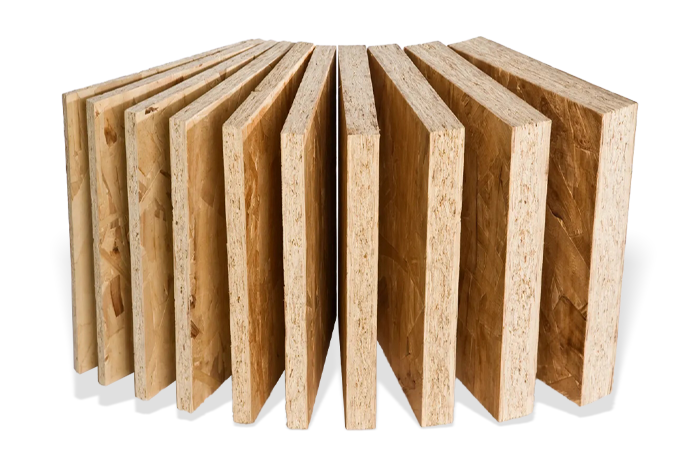

The hot pressing curing process of moisture-proof green particleboard is the key link in the production process. The following is its specific introduction:

1. preparation before hot pressing

Slab inspection: check the slab after paving and preloading to ensure that its thickness is uniform, its surface is flat, and there is no obvious accumulation or vacancy of shavings. At the same time, confirm that the moisture content of the slab meets the hot pressing requirements, generally about 8%-12%.

Hot press commissioning: adjust the parameters of the hot press, including pressure, temperature, hot pressing time, etc., according to the specification and product requirements of the slab. At the same time, check whether the heating system and hydraulic system of the hot press operate normally to ensure that the hot press process can be carried out stably.

2. plate loading and vehicle entry

Plate loading: put the slabs neatly between the pads of the hot press, and pay attention to the correct placement of slabs to avoid deflection or dislocation, so as not to affect the hot press effect. For some large hot presses, it may be necessary to use special plate mounting equipment to improve the efficiency and correctness of plate mounting.

Vehicle entry: after plate loading, push the pad car of the hot press into the hot press, start the closing device of the hot press, make the upper and lower pressing plates gradually close to the slab, and start to apply pressure.

3. hot pressing process

Pressure rise stage: the hot press starts to apply pressure to the slab, and the pressure gradually rises to the set value. In this process, the air in the slab is gradually discharged, the distance between the shavings is gradually reduced, and the adhesive begins to be evenly distributed on the surface of the shavings under the action of pressure. The pressure rise speed should not be too fast to avoid damage to the internal structure of the slab or adhesive overflow.

Heating stage: at the same time of boosting, the heating system of the hot press starts to work to raise the temperature of the pressing plate to the set hot pressing temperature, which is generally between 160 ℃ -200 ℃. The heat is transferred to the slab through the pressing plate, so that the adhesive in the slab can be cured rapidly, and at the same time, the moisture in the shavings can be evaporated, further improving the strength and performance of the plate. During the heating process, the temperature uniformity shall be maintained to avoid local overheating or supercooling.

Pressure maintaining stage: enter the pressure maintaining stage when the pressure and temperature reach the set value. In the pressure maintaining stage, the pressure and temperature remain stable to fully cure the adhesive and form a firm bond between the shavings. The pressure holding time is determined according to the thickness, density, adhesive performance and other factors of the plate, generally 1-5 minutes/mm plate thickness.

Depressurization stage: after pressure maintaining, gradually reduce the pressure of the hot press, so that the slab is cooled and shaped under the gradually reduced pressure. The pressure reduction speed should not be too fast, so as to avoid the internal stress of the plate, resulting in the deformation or cracking of the plate.

4. plate removal and cooling

Unloading: when the pressure drops to zero, open the hot press, push the skid truck out of the hot press, and then use the unloading equipment to remove the hot pressed particleboard from the skid. When removing the plate, pay attention to avoid collision and scratching the surface of the plate.

Cooling: the temperature of the particleboard after unloading is relatively high, so it needs to be cooled to reduce its temperature to about room temperature. There are two kinds of cooling methods: natural cooling and forced cooling. The natural cooling time is long, but the internal stress distribution of the plate is relatively uniform; Forced cooling can accelerate the cooling speed by air cooling or water cooling, but pay attention to control the cooling speed to avoid excessive internal stress of the plate.

The parameters (pressure, temperature, time, etc.) in the hot pressing curing process need to be reasonably adjusted and optimized according to the specific specifications of particleboard, raw material characteristics and types of adhesives, so as to ensure that the moisture-proof green particleboard produced has good physical and mechanical properties and moisture-proof performance.

1. preparation before hot pressing

Slab inspection: check the slab after paving and preloading to ensure that its thickness is uniform, its surface is flat, and there is no obvious accumulation or vacancy of shavings. At the same time, confirm that the moisture content of the slab meets the hot pressing requirements, generally about 8%-12%.

Hot press commissioning: adjust the parameters of the hot press, including pressure, temperature, hot pressing time, etc., according to the specification and product requirements of the slab. At the same time, check whether the heating system and hydraulic system of the hot press operate normally to ensure that the hot press process can be carried out stably.

2. plate loading and vehicle entry

Plate loading: put the slabs neatly between the pads of the hot press, and pay attention to the correct placement of slabs to avoid deflection or dislocation, so as not to affect the hot press effect. For some large hot presses, it may be necessary to use special plate mounting equipment to improve the efficiency and correctness of plate mounting.

Vehicle entry: after plate loading, push the pad car of the hot press into the hot press, start the closing device of the hot press, make the upper and lower pressing plates gradually close to the slab, and start to apply pressure.

3. hot pressing process

Pressure rise stage: the hot press starts to apply pressure to the slab, and the pressure gradually rises to the set value. In this process, the air in the slab is gradually discharged, the distance between the shavings is gradually reduced, and the adhesive begins to be evenly distributed on the surface of the shavings under the action of pressure. The pressure rise speed should not be too fast to avoid damage to the internal structure of the slab or adhesive overflow.

Heating stage: at the same time of boosting, the heating system of the hot press starts to work to raise the temperature of the pressing plate to the set hot pressing temperature, which is generally between 160 ℃ -200 ℃. The heat is transferred to the slab through the pressing plate, so that the adhesive in the slab can be cured rapidly, and at the same time, the moisture in the shavings can be evaporated, further improving the strength and performance of the plate. During the heating process, the temperature uniformity shall be maintained to avoid local overheating or supercooling.

Pressure maintaining stage: enter the pressure maintaining stage when the pressure and temperature reach the set value. In the pressure maintaining stage, the pressure and temperature remain stable to fully cure the adhesive and form a firm bond between the shavings. The pressure holding time is determined according to the thickness, density, adhesive performance and other factors of the plate, generally 1-5 minutes/mm plate thickness.

Depressurization stage: after pressure maintaining, gradually reduce the pressure of the hot press, so that the slab is cooled and shaped under the gradually reduced pressure. The pressure reduction speed should not be too fast, so as to avoid the internal stress of the plate, resulting in the deformation or cracking of the plate.

4. plate removal and cooling

Unloading: when the pressure drops to zero, open the hot press, push the skid truck out of the hot press, and then use the unloading equipment to remove the hot pressed particleboard from the skid. When removing the plate, pay attention to avoid collision and scratching the surface of the plate.

Cooling: the temperature of the particleboard after unloading is relatively high, so it needs to be cooled to reduce its temperature to about room temperature. There are two kinds of cooling methods: natural cooling and forced cooling. The natural cooling time is long, but the internal stress distribution of the plate is relatively uniform; Forced cooling can accelerate the cooling speed by air cooling or water cooling, but pay attention to control the cooling speed to avoid excessive internal stress of the plate.

The parameters (pressure, temperature, time, etc.) in the hot pressing curing process need to be reasonably adjusted and optimized according to the specific specifications of particleboard, raw material characteristics and types of adhesives, so as to ensure that the moisture-proof green particleboard produced has good physical and mechanical properties and moisture-proof performance.

Previous:

Why use odorless E0 grade environmentally friendl…

Next:

What are the specific applications of ENF board i…

Related articles

Related products

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell