You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

Why is odorless E0 grade environmentally friendly particleboard compatible with other decorative mat

source:www.cypanlong.cn Time:2025-09-22

Odorless E0 grade environmentally friendly particleboard can be compatible with various decorative materials such as PVC, melamine paper, and solid wood veneer. The core reason is that its surface physical properties are adapted, processing technology compatibility is strong, and environmental properties are conflict free. Specific analysis can be carried out from the following four aspects:

1、 The surface flatness and roughness meet the standard, providing the "basic conditions" for the bonding of the decorative surface

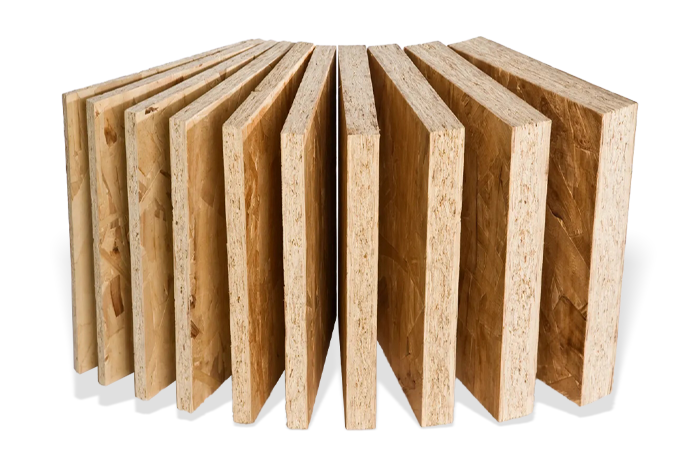

The bonding effect of decorative materials such as melamine paper and PVC film first depends on the "flatness" of the substrate surface - if the substrate surface is uneven, it will cause bubbles, wrinkles, or local peeling of the decorative surface. Odorless E0 grade environmentally friendly particleboard undergoes sanding treatment during production:

After sanding, the surface roughness (Ra value) is usually ≤ 1.6 μ m, much lower than that of ordinary particleboard (Ra value is mostly 3.2-6.3 μ m). The surface is delicate without obvious particle sensation, and can achieve a "tight fit" with the contact surface of the decorative material, reducing air residue;

The thickness deviation is strictly controlled (± 0.3mm is allowed for high-quality products), and the overall flatness of the board is high. When splicing or large-area finishing, there will be no warping of the finish due to uneven local thickness, and it is suitable for various finishing processes that require "seamless bonding" (such as hot pressing and cold pressing).

2、 The substrate density is uniform and the internal stress is stable, avoiding the "stress cracking" of the finish

Different decorative materials (such as thinner veneer and stronger toughness of PVC film) have different requirements for the "density uniformity" and "dimensional stability" of the substrate. If the substrate density is uneven, local pressure differences during hot pressing bonding will cause deformation of the decorative surface; If the internal stress of the substrate is high, it is prone to warping in the later stage, which can lead to tearing of the finish. Odorless E0 grade environmentally friendly particleboard ensures compatibility through two major processes in production:

Symmetrical paving process: The shavings are distributed in a symmetrical structure of "fine material coarse material fine material", with a high density of the upper and lower surface layers (about 0.75-0.85g/cm 3) and a moderate density of the core layer (about 0.6-0.7g/cm 3). This not only ensures that the surface hardness is sufficient to support the finish (to avoid pressure and depression of the finish), but also offsets internal stress through a symmetrical structure, making it less prone to warping during long-term use and reducing the risk of cracking caused by substrate deformation of the finish;

High temperature hot pressing curing is sufficient: In production, 180-220 ℃ high temperature and 2.5-3.5MPa high pressure hot pressing are used, and adhesives (such as MDI glue and plant protein glue) are cured more fully. The internal structure of the substrate is compact, and the density fluctuation range is ≤ 5% (ordinary particleboard is mostly 8-10%). The pressure can be evenly transmitted when bonding the veneer, and it is suitable for different hot pressing parameters of the veneer material (such as 180-200 ℃ for melamine paper and 120-150 ℃ for solid wood veneer).

3、 Environmentally friendly adhesives and decorative materials have no chemical conflicts and do not produce adverse reactions

If formaldehyde containing urea formaldehyde resin adhesive is used for ordinary particleboard, the residual volatiles in the adhesive may react chemically with the decorative materials (such as plasticizers for PVC film and natural resins for solid wood veneer), causing discoloration, odor, and even reducing the bonding strength. The adhesive properties of odorless E0 grade environmentally friendly particleboard avoid this problem from the root:

The mainstream uses formaldehyde free adhesives (such as MDI adhesive and soy protein adhesive), which do not contain volatile organic compounds such as formaldehyde and benzene. When in contact with decorative materials, there is no "chemical conflict" - it will not corrode the molecular structure of PVC film, nor will it react with the natural components of solid wood veneer to cause discoloration, ensuring the stability and durability of the appearance of the decoration;

During the high-temperature hot pressing process, the residual volatile compounds of the adhesive have been basically removed (and the odor has also been eliminated), and the surface will not bubble due to the "secondary release of volatile compounds" from the substrate after bonding, making it suitable for scenarios with high "chemical stability" requirements (such as children's furniture, indoor decoration).

4、 Strong processing adaptability, compatible with multiple veneer bonding processes

Different decorative materials require different bonding processes (such as hot pressing, cold pressing, and coating), and the physical properties (hardness, moisture content) of odorless E0 grade environmentally friendly particleboard can be adapted to these processes:

For melamine impregnated paper: The surface hardness of the substrate is sufficient, and during hot pressing, the resin in the paper can be fully cured and bonded to the substrate. The peel strength is ≥ 1.5N/mm (far exceeding the national standard of 1.0N/mm), and it is not easy to peel off;

For PVC film: The moisture content of the substrate should be controlled within 6-12% (suitable range for decorative materials). When cold pressed or vacuum formed, the PVC film can tightly wrap around the edges of the substrate (especially the irregular edges after milling), without "later shrinkage cracking" caused by fluctuations in the moisture content of the substrate;

For solid wood veneer: The surface of the substrate is delicate and can be bonded by applying glue and cold pressing or hot pressing. Solid wood veneer is not easily exposed due to the granular texture of the substrate surface, and the environmental friendliness of the substrate matches the natural properties of solid wood veneer, meeting the environmental protection needs of furniture.

1、 The surface flatness and roughness meet the standard, providing the "basic conditions" for the bonding of the decorative surface

The bonding effect of decorative materials such as melamine paper and PVC film first depends on the "flatness" of the substrate surface - if the substrate surface is uneven, it will cause bubbles, wrinkles, or local peeling of the decorative surface. Odorless E0 grade environmentally friendly particleboard undergoes sanding treatment during production:

After sanding, the surface roughness (Ra value) is usually ≤ 1.6 μ m, much lower than that of ordinary particleboard (Ra value is mostly 3.2-6.3 μ m). The surface is delicate without obvious particle sensation, and can achieve a "tight fit" with the contact surface of the decorative material, reducing air residue;

The thickness deviation is strictly controlled (± 0.3mm is allowed for high-quality products), and the overall flatness of the board is high. When splicing or large-area finishing, there will be no warping of the finish due to uneven local thickness, and it is suitable for various finishing processes that require "seamless bonding" (such as hot pressing and cold pressing).

2、 The substrate density is uniform and the internal stress is stable, avoiding the "stress cracking" of the finish

Different decorative materials (such as thinner veneer and stronger toughness of PVC film) have different requirements for the "density uniformity" and "dimensional stability" of the substrate. If the substrate density is uneven, local pressure differences during hot pressing bonding will cause deformation of the decorative surface; If the internal stress of the substrate is high, it is prone to warping in the later stage, which can lead to tearing of the finish. Odorless E0 grade environmentally friendly particleboard ensures compatibility through two major processes in production:

Symmetrical paving process: The shavings are distributed in a symmetrical structure of "fine material coarse material fine material", with a high density of the upper and lower surface layers (about 0.75-0.85g/cm 3) and a moderate density of the core layer (about 0.6-0.7g/cm 3). This not only ensures that the surface hardness is sufficient to support the finish (to avoid pressure and depression of the finish), but also offsets internal stress through a symmetrical structure, making it less prone to warping during long-term use and reducing the risk of cracking caused by substrate deformation of the finish;

High temperature hot pressing curing is sufficient: In production, 180-220 ℃ high temperature and 2.5-3.5MPa high pressure hot pressing are used, and adhesives (such as MDI glue and plant protein glue) are cured more fully. The internal structure of the substrate is compact, and the density fluctuation range is ≤ 5% (ordinary particleboard is mostly 8-10%). The pressure can be evenly transmitted when bonding the veneer, and it is suitable for different hot pressing parameters of the veneer material (such as 180-200 ℃ for melamine paper and 120-150 ℃ for solid wood veneer).

3、 Environmentally friendly adhesives and decorative materials have no chemical conflicts and do not produce adverse reactions

If formaldehyde containing urea formaldehyde resin adhesive is used for ordinary particleboard, the residual volatiles in the adhesive may react chemically with the decorative materials (such as plasticizers for PVC film and natural resins for solid wood veneer), causing discoloration, odor, and even reducing the bonding strength. The adhesive properties of odorless E0 grade environmentally friendly particleboard avoid this problem from the root:

The mainstream uses formaldehyde free adhesives (such as MDI adhesive and soy protein adhesive), which do not contain volatile organic compounds such as formaldehyde and benzene. When in contact with decorative materials, there is no "chemical conflict" - it will not corrode the molecular structure of PVC film, nor will it react with the natural components of solid wood veneer to cause discoloration, ensuring the stability and durability of the appearance of the decoration;

During the high-temperature hot pressing process, the residual volatile compounds of the adhesive have been basically removed (and the odor has also been eliminated), and the surface will not bubble due to the "secondary release of volatile compounds" from the substrate after bonding, making it suitable for scenarios with high "chemical stability" requirements (such as children's furniture, indoor decoration).

4、 Strong processing adaptability, compatible with multiple veneer bonding processes

Different decorative materials require different bonding processes (such as hot pressing, cold pressing, and coating), and the physical properties (hardness, moisture content) of odorless E0 grade environmentally friendly particleboard can be adapted to these processes:

For melamine impregnated paper: The surface hardness of the substrate is sufficient, and during hot pressing, the resin in the paper can be fully cured and bonded to the substrate. The peel strength is ≥ 1.5N/mm (far exceeding the national standard of 1.0N/mm), and it is not easy to peel off;

For PVC film: The moisture content of the substrate should be controlled within 6-12% (suitable range for decorative materials). When cold pressed or vacuum formed, the PVC film can tightly wrap around the edges of the substrate (especially the irregular edges after milling), without "later shrinkage cracking" caused by fluctuations in the moisture content of the substrate;

For solid wood veneer: The surface of the substrate is delicate and can be bonded by applying glue and cold pressing or hot pressing. Solid wood veneer is not easily exposed due to the granular texture of the substrate surface, and the environmental friendliness of the substrate matches the natural properties of solid wood veneer, meeting the environmental protection needs of furniture.

Previous:

What issues should be noted during the processing…

Next:

Why do kindergartens choose formaldehyde free ENF…

Related articles

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell