You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

Why is ENF board is used suitable for high environmental requirement places

source:www.cypanlong.cn Time:2025-06-16

The core reason why formaldehyde free ENF grade environmentally friendly particleboard is suitable for places with high environmental requirements is that it achieves a dual breakthrough in environmental protection and functionality from three dimensions: "source control+process optimization+performance guarantee". The following is a specific analysis:

1、 Formaldehyde release approaching zero, eliminating pollution from the source

1. Core applications of formaldehyde free adhesives

Using MDI adhesive (isocyanate adhesive) or bio based adhesive, this type of adhesive itself does not contain formaldehyde components, which is different from traditional urea formaldehyde resin adhesive (synthesized from formaldehyde as raw material). For example, MDI adhesive forms a stable polymer after curing, which does not decompose and release formaldehyde, cutting off the main source of formaldehyde pollution from the production source.

The formaldehyde emission standard is strict: according to relevant standards, ENF level requires formaldehyde emission to be ≤ 0.025mg/m 3, far lower than E0 level (≤ 0.050mg/m 3) and E1 level (≤ 0.124mg/m 3), and even close to the formaldehyde emission level of natural wood (natural wood also releases trace amounts of formaldehyde due to its own metabolism, usually ≤ 0.03mg/m 3), which almost does not cause indoor air pollution.

2. Formaldehyde control in raw materials and production processes

Select low formaldehyde natural wood (such as pine and poplar), avoid using recycled waste or inferior raw materials containing formaldehyde additives, and reduce the initial formaldehyde content of the board from the source.

No formaldehyde containing additives (such as preservatives and curing agents) are added during the production process to avoid secondary pollution.

2、 Process optimization reduces harmful substance residues and enhances environmental stability

1. Correct control of hot pressing and drying processes

Optimization of hot pressing parameters: By controlling the hot pressing temperature (usually 180-220 ℃), pressure (1.0-1.5MPa), and time (3-5 minutes), the adhesive is completely cured to avoid slow release of formaldehyde in the later stage due to incomplete curing. Meanwhile, high-temperature and high-pressure processes can further decompose trace amounts of natural formaldehyde that may exist in wood.

Drying process meets the standard: controlling the moisture content of wood at 8% -12%. If the moisture content is too low, it can easily cause cracking of the board, while if it is too high, it may promote microbial growth or adhesive decomposition. Proper moisture control can reduce environmental triggers for formaldehyde release.

2. Surface treatment enhances the sealing effect

Using excellent edge sealing strips and techniques (such as PUR hot melt adhesive edge sealing), the edges of the board are completely sealed to prevent the release of trace amounts of volatile substances that may exist inside; Surface veneers (such as melamine veneer, PET film) form a physical barrier, further reducing the possibility of formaldehyde volatilization from the surface.

3、 Good physical performance, meeting the durability requirements of high environmental protection scenarios

1. Balancing strength and stability

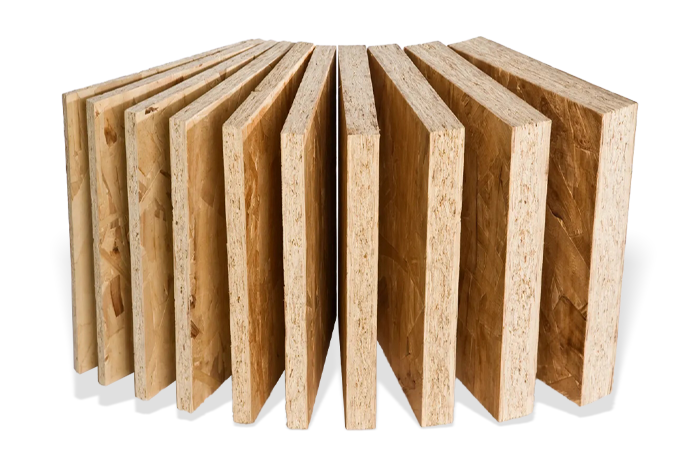

Formaldehyde free particleboard has a uniform density (usually 650-750kg/m 3), with internal particles arranged in a staggered manner. After hot pressing, it forms a high-strength structure with a bending strength of ≥ 15MPa and an elastic modulus of ≥ 1500MPa. It has strong deformation resistance and is suitable for making long-term furniture (such as wardrobes and cabinets), avoiding internal material exposure due to board cracking and deformation, indirectly ensuring environmental protection.

Some products add moisture-proof factors or use waterproof finishes to prevent expansion and deformation in damp environments such as kitchens and bathrooms, reducing the risk of adhesive exposure caused by board damage.

2. Multi functional adaptation to special scenarios

Some products have achieved B1 level fire protection standards through flame retardant treatment (adding formaldehyde free flame retardants), and are suitable for public places such as hospitals and schools that have requirements for fire prevention and environmental protection; Silver ion antibacterial agent is added to the surface of antibacterial formaldehyde free particleboard, which can prevent bacterial growth and is suitable for easily accessible scenarios such as children's rooms and hospital wards.

4、 Authoritative certification and testing endorsement, ensuring environmental reliability

1. Third party testing strictly controls

Testing by CNAS certified laboratories (such as climate chamber testing) is required, and the testing process simulates the actual indoor environment (temperature 23 ± 0.5 ℃, humidity 45 ± 5%) to ensure that the data truly reflects the formaldehyde emissions in the usage scenario.

Obtained ENF certification (such as certification from the China Forestry Industry Association), and some products have also passed international certifications (such as CARB EPA NAF certification from the United States and CE certification from the European Union). Environmental standards are in line with international standards, making them suitable for places with high certification requirements (such as kindergartens and foreign-related institutions).

5、 Application analysis of typical high environmental protection scenarios

Children's room/maternity room: Infants, young children, and pregnant women are more sensitive to pollutants such as formaldehyde. Non formaldehyde ENF grade boards can control indoor formaldehyde concentration within a safe threshold, reducing the risk of respiratory diseases, allergies, or fetal developmental abnormalities.

School/Kindergarten: With dense population and long-term stay, the release of formaldehyde from boards can easily lead to collective health problems. ENF grade boards, combined with ventilation design, can ensure indoor air quality meets standards (such as GB/T 18883-2022 requiring indoor formaldehyde to be ≤ 0.08mg/m 3).

Hospital ward: It is necessary to meet both environmental protection and antibacterial needs. Formaldehyde free panels with antibacterial finishes can reduce formaldehyde and bacterial growth, providing a safe environment for patients.

Residential/furnished rooms: Homeowners have high requirements for living quality, and ENF grade panels can be used as the core material for "zero formaldehyde decoration", combined with low VOC coatings, formaldehyde free flooring, etc., to achieve environmental upgrades of the overall space.

1、 Formaldehyde release approaching zero, eliminating pollution from the source

1. Core applications of formaldehyde free adhesives

Using MDI adhesive (isocyanate adhesive) or bio based adhesive, this type of adhesive itself does not contain formaldehyde components, which is different from traditional urea formaldehyde resin adhesive (synthesized from formaldehyde as raw material). For example, MDI adhesive forms a stable polymer after curing, which does not decompose and release formaldehyde, cutting off the main source of formaldehyde pollution from the production source.

The formaldehyde emission standard is strict: according to relevant standards, ENF level requires formaldehyde emission to be ≤ 0.025mg/m 3, far lower than E0 level (≤ 0.050mg/m 3) and E1 level (≤ 0.124mg/m 3), and even close to the formaldehyde emission level of natural wood (natural wood also releases trace amounts of formaldehyde due to its own metabolism, usually ≤ 0.03mg/m 3), which almost does not cause indoor air pollution.

2. Formaldehyde control in raw materials and production processes

Select low formaldehyde natural wood (such as pine and poplar), avoid using recycled waste or inferior raw materials containing formaldehyde additives, and reduce the initial formaldehyde content of the board from the source.

No formaldehyde containing additives (such as preservatives and curing agents) are added during the production process to avoid secondary pollution.

2、 Process optimization reduces harmful substance residues and enhances environmental stability

1. Correct control of hot pressing and drying processes

Optimization of hot pressing parameters: By controlling the hot pressing temperature (usually 180-220 ℃), pressure (1.0-1.5MPa), and time (3-5 minutes), the adhesive is completely cured to avoid slow release of formaldehyde in the later stage due to incomplete curing. Meanwhile, high-temperature and high-pressure processes can further decompose trace amounts of natural formaldehyde that may exist in wood.

Drying process meets the standard: controlling the moisture content of wood at 8% -12%. If the moisture content is too low, it can easily cause cracking of the board, while if it is too high, it may promote microbial growth or adhesive decomposition. Proper moisture control can reduce environmental triggers for formaldehyde release.

2. Surface treatment enhances the sealing effect

Using excellent edge sealing strips and techniques (such as PUR hot melt adhesive edge sealing), the edges of the board are completely sealed to prevent the release of trace amounts of volatile substances that may exist inside; Surface veneers (such as melamine veneer, PET film) form a physical barrier, further reducing the possibility of formaldehyde volatilization from the surface.

3、 Good physical performance, meeting the durability requirements of high environmental protection scenarios

1. Balancing strength and stability

Formaldehyde free particleboard has a uniform density (usually 650-750kg/m 3), with internal particles arranged in a staggered manner. After hot pressing, it forms a high-strength structure with a bending strength of ≥ 15MPa and an elastic modulus of ≥ 1500MPa. It has strong deformation resistance and is suitable for making long-term furniture (such as wardrobes and cabinets), avoiding internal material exposure due to board cracking and deformation, indirectly ensuring environmental protection.

Some products add moisture-proof factors or use waterproof finishes to prevent expansion and deformation in damp environments such as kitchens and bathrooms, reducing the risk of adhesive exposure caused by board damage.

2. Multi functional adaptation to special scenarios

Some products have achieved B1 level fire protection standards through flame retardant treatment (adding formaldehyde free flame retardants), and are suitable for public places such as hospitals and schools that have requirements for fire prevention and environmental protection; Silver ion antibacterial agent is added to the surface of antibacterial formaldehyde free particleboard, which can prevent bacterial growth and is suitable for easily accessible scenarios such as children's rooms and hospital wards.

4、 Authoritative certification and testing endorsement, ensuring environmental reliability

1. Third party testing strictly controls

Testing by CNAS certified laboratories (such as climate chamber testing) is required, and the testing process simulates the actual indoor environment (temperature 23 ± 0.5 ℃, humidity 45 ± 5%) to ensure that the data truly reflects the formaldehyde emissions in the usage scenario.

Obtained ENF certification (such as certification from the China Forestry Industry Association), and some products have also passed international certifications (such as CARB EPA NAF certification from the United States and CE certification from the European Union). Environmental standards are in line with international standards, making them suitable for places with high certification requirements (such as kindergartens and foreign-related institutions).

5、 Application analysis of typical high environmental protection scenarios

Children's room/maternity room: Infants, young children, and pregnant women are more sensitive to pollutants such as formaldehyde. Non formaldehyde ENF grade boards can control indoor formaldehyde concentration within a safe threshold, reducing the risk of respiratory diseases, allergies, or fetal developmental abnormalities.

School/Kindergarten: With dense population and long-term stay, the release of formaldehyde from boards can easily lead to collective health problems. ENF grade boards, combined with ventilation design, can ensure indoor air quality meets standards (such as GB/T 18883-2022 requiring indoor formaldehyde to be ≤ 0.08mg/m 3).

Hospital ward: It is necessary to meet both environmental protection and antibacterial needs. Formaldehyde free panels with antibacterial finishes can reduce formaldehyde and bacterial growth, providing a safe environment for patients.

Residential/furnished rooms: Homeowners have high requirements for living quality, and ENF grade panels can be used as the core material for "zero formaldehyde decoration", combined with low VOC coatings, formaldehyde free flooring, etc., to achieve environmental upgrades of the overall space.

Previous:

Applications of odorless E0-grade eco-friendly pa…

Next:

Which groups of people will use odorless E0 grade…

Related articles

Related products

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell