News Navigation

When discussing whether families with infants and young children should avoid formaldehyde free ENF grade environmentally friendly particleboard, the core is not to deny the environmental friendliness of the board, but to combine the physiological characteristics of infants and young children (delicate respiratory tract, sensitive skin, and special activity patterns), and pay attention to the three core issues of the limited definition of "formaldehyde free", the hidden risks of board production, and the cumulative effects of usage scenarios. Although the formaldehyde emission level of ENF grade artificial boards and their products is relatively low (≤ 0.025mg/m 3), for families with infants and young children, it is still necessary to be alert to non formaldehyde risks and potential problems in actual use. The specific reasons are as follows:

1、 'No formaldehyde added' ≠ 'No harmful substances', non formaldehyde risks are more sensitive to infants and young children

The core of ENF grade "formaldehyde free board" is that "no formaldehyde containing adhesives are added during the production process" (such as using MDI adhesive instead of urea formaldehyde adhesive), but it is not completely free of other volatile organic compounds (VOCs) or harmful substances, and infants and young children have a much lower tolerance to these substances than peoples:

1. The implicit components of the adhesive itself

The commonly used MDI adhesive (diphenylmethane diisocyanate) for formaldehyde free boards may release trace amounts of isocyanate like substances (MDI monomers) during production or board aging processes, although it does not contain formaldehyde; Some low-priced formaldehyde free boards may be mixed with a small amount of other low formaldehyde adhesives, and may still be accompanied by the release of trace amounts of phenolic and amine substances. These substances may not cause significant harm to peoples, but infants and young children have thin respiratory mucosa and high respiratory rates (about 40 times per minute, twice that of peoples). Long term exposure may cause allergic reactions such as coughing, sneezing, and skin rash.

2. VOCs from wood itself and additives

The raw materials of particleboard (wood shavings, straw, etc.) themselves release natural VOCs such as terpenes and aldehydes (non formaldehyde, such as acetaldehyde and acetaldehyde); In order to improve the waterproof and abrasion resistance of the board during production, waterproof agents (such as paraffin lotion), preservatives (such as boric acid) and flame retardants may be added, and these additives may also slowly release trace substances. Infants and young children who spend a long time around particleboard furniture such as floors, wardrobes, toy cabinets, etc. (such as crawling and gnawing on the edges of furniture), have close contact distance and long exposure time, and are at a higher risk than peoples.

2、 The physical structural characteristics of particleboard pose safety hazards and cleaning difficulties for infants and young children

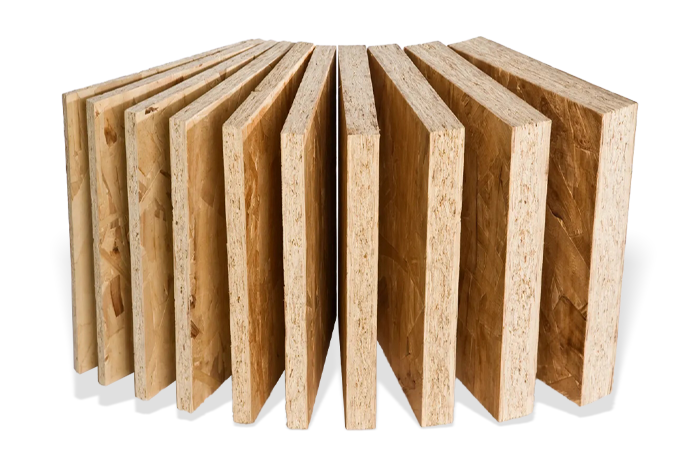

Compared to solid wood and multi-layer solid wood panels, the "particle splicing+surface pasting" structure of particleboard poses additional risks in infant activity scenarios and is more difficult to clean:

1. Physical security: Easy to break and release small particles

The density of particleboard is relatively low (usually 0.6-0.8g/cm 3, lower than that of solid wood (0.7-1.0g/cm 3). If the surface pasting process is not good (such as the edge sealing is not firm), it is easy for infants and young children to scratch and bite, causing the pasting to fall off and exposing loose wood chips inside. If these small particles (diameter may be less than 0.1mm) are inhaled into the respiratory tract by infants and young children, they may cause respiratory obstruction or bronchitis; If ingested by mistake, it may also cause gastrointestinal discomfort.

2. Difficulty in cleaning: easy to accumulate dirt and grime, and breed bacteria/mold

The porosity of particleboard is relatively high (with small gaps inside due to particle splicing). If used in high-frequency contact areas such as floors and dining chairs, food residues (such as milk powder and food debris), sweat, and urine from infants and young children are prone to seep into the gaps of the board, making it difficult to clean. In the long run, it is easy to breed fine bacteria (such as E. coli) and mold (such as Aspergillus niger). Direct contact between infant and toddler skin and contaminated board surfaces, or biting fingers after contact, may cause skin infections or gastrointestinal problems.

3、 The 'superposition effect' amplifies the risk: when multiple pieces of furniture are used together in a household, the concentration of pollutants is prone to exceed the standard

The formaldehyde emission of ENF grade board is the "detection value of a single board under standard laboratory conditions" (1m 3 climate chamber method), but in actual household use, placing multiple pieces of particleboard furniture at the same time (such as wardrobes, desks, baby crib bed boards, toy storage cabinets) often produces a "pollutant stacking effect":

Even if the VOCs emission of a single board meets the standard (such as the emission of each wardrobe ≤ 0.1mg/m 3), if 3-5 pieces of similar furniture are placed in the children's room at the same time, the indoor VOCs concentration after stacking may exceed the limit of 0.6mg/m 3 specified in the Indoor Air Quality Standard (GB/T 18883-2002). Infants and young children exposed to excessive trace pollutants in enclosed children's rooms (such as during nighttime sleep) may affect the development of the immune system and increase the risk of allergies, asthma, and other diseases.

In addition, the release of pollutants from particleboard is greatly affected by temperature and humidity (VOCs release may increase by 1-2 times for every 10 ℃ temperature increase). If heating is frequently used in winter and air conditioning is frequently used in summer, or if the humidity is high during the southern rainy season, the release of pollutants will be accelerated, further amplifying the risk.

4、 It's not 'completely unusable', but requires stricter 'selection+usage standards'

For families with infants and young children, it is not forbidden to use formaldehyde free ENF grade particleboard, but rather to reduce risks through stricter screening and usage methods:

1. Prioritize selecting products with "all material formaldehyde free+high-density structure"

Select high-density particleboard (density ≥ 0.8g/cm 3) with clear labeling of "MDI adhesive full process" and "no added preservatives/flame retardants", use food grade PVC or solid wood veneer for surface coating, and use "pur hot melt adhesive edge sealing" for edge sealing (more secure than ordinary EVA edge sealing, reducing gaps).

2. Control usage and avoid dense placement

The proportion of particleboard furniture in children's rooms should not exceed 50%, and it is recommended to avoid placing more than 3 large pieces of particleboard furniture (such as wardrobes, desks, and storage cabinets) at the same time; Prioritize using solid wood furniture (such as pine and beech wood) as a substitute, or choose multi-layer solid wood panels or particleboard (with more stable physical structure and less pollutant release).

3. Strengthen ventilation and cleaning to reduce exposure risks

After the arrival of new furniture, the children's room should be ventilated for at least 8 hours a day (in high temperature seasons, fans can be used to accelerate air circulation), and continue to ventilate for 3-6 months before allowing infants and young children to use it; Regularly wipe the surface of particleboard furniture (especially the edge gaps) with a damp cloth in daily life to avoid the accumulation of food residues; If the floor is made of particleboard substrate, anti slip pads should be laid to reduce wear and pollutant release.

Related articles

Home

Home

Wechat

Wechat

Tell

Tell